Eco Pickled Surface - Lloyds Engineering Works Ltd

- Home

- Eco Pickled Surface

Lloyds Engineering Works Ltd paves the way for a greener future with Eco Pickled Surface Technology and partners with The Material Works Ltd

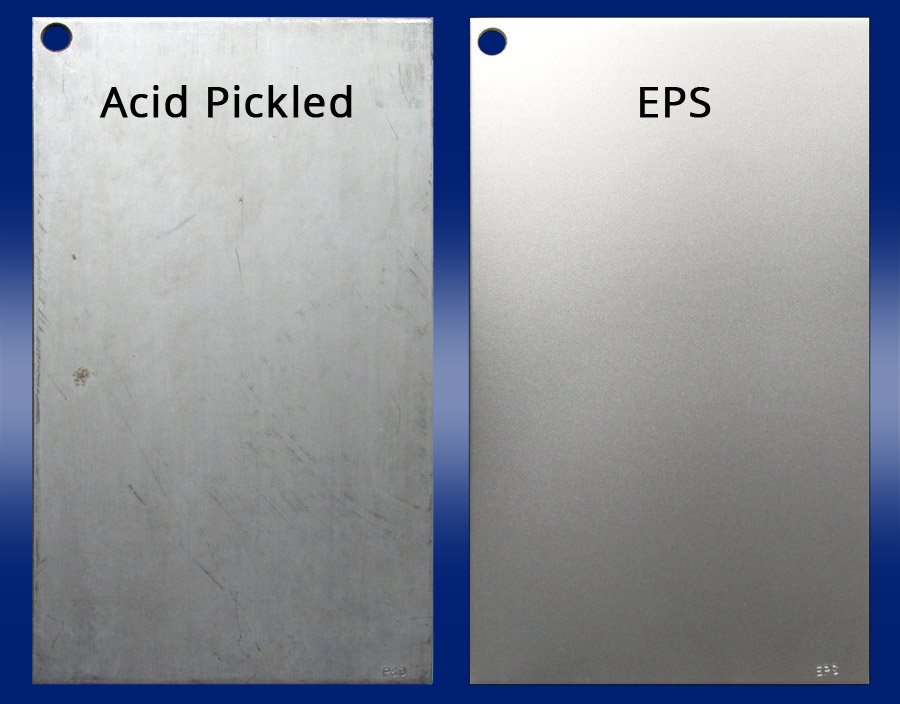

Steel is the backbone of our world, from towering skyscrapers to the cars we drive. But traditional steel processing methods come at a cost to the environment, relying on harsh acids that pollute and pose safety risks.

That's where we, Lloyds Engineering Works Ltd, a name synonymous with innovation and excellence in the steel industry, is stepping up to the plate. Through a groundbreaking Memorandum of Understanding (MoU) with The Material Works Ltd on 27 September 2023, we are embracing a revolutionary Eco Pickled Surface (EPS Gen 4) technology that's set to transform the industry!

But this isn't just about another technological advancement. This is about building a sustainable future for steel.

No more hazardous acids: EPS Gen 4 eliminates the need for harmful acids, creating a safer work environment for employees and reducing the environmental impact of steel processing.

A cleaner planet: By minimizing waste and pollution, Lloyds is contributing to a healthier planet for generations to come.

Cost-effective innovation: This asset-light technology optimizes resource allocation, making it a win-win for both the environment and your bottom line.

Advanced performance: Don't let the eco-friendly label fool you. EPS Gen 4 delivers superior results for various steel grades, ensuring the same high quality you expect from Lloyds.

This partnership isn't just a milestone, it's a giant leap for the steel industry as a whole. We are committed to leading the charge towards sustainable steel processing, and with EPS Gen 4, they're well on their way.

The impact of this collaboration is far-reaching:

Supporting “Make in India": The localized manufacturing of EPS Gen 4 technology empowers domestic growth and aligns with the government's initiative.

Empowering the future: This technology transfer paves the way for innovation and sustainability in the Indian and Bangladeshi steel markets

Setting a global example: Lloyds is showcasing its commitment to environmental responsibility, inspiring other companies to follow suit

This is more than just steel processing; it's a commitment to a better tomorrow.

Join us on this journey towards a greener future. Explore the transformative power of Eco Pickled Surface technology and discover how it's changing the game for a sustainable steel industry.

Let’s unveiling the vital role of Steel Pickling Across Industries

Pickling is a crucial process in the steel industry that involves the removal of surface oxides and impurities from steel surfaces. This procedure is typically conducted using an acidic solution, such as hydrochloric acid or sulfuric acid, to dissolve the scale formed during hot rolling or heat treatment.

The pickling process results in a clean, smooth surface on the steel, which improves its appearance, enhances adhesion properties for subsequent coating or painting, and ensures better corrosion resistance.

Now let’s look at the industries steel pickling plays a vital role in

Automotive Industry

Pickled steel is extensively used in the automotive sector for manufacturing various components, including body panels, chassis, and structural parts. The clean surface achieved through pickling enables better welding and painting processes, contributing to the production of high-quality vehicles with superior finish and durability.

Construction and Infrastructure

In the construction industry, pickled steel finds application in the fabrication of structural beams, columns, and other components used in building construction, bridges, and infrastructure projects. The removal of scale and impurities ensures better weldability and improves the overall aesthetic appeal of steel structures.

Appliances and Household Goods

Manufacturers of appliances and household goods utilize pickled steel for producing items such as kitchen appliances, furniture, and HVAC systems. The clean surface obtained through pickling enhances the appearance and longevity of these products.

Pipelines and Oil & Gas Industry

Pickled steel is also employed in the production of pipes and tubing used in the oil and gas sector. The removal of surface oxides ensures the integrity and performance of pipelines, facilitating the transportation of oil, gas, and other fluids.

Forecasting the Next Decade: Charting the Course for Pickled Steel Production Growth

Embarking on a journey into the future of steel production, we analyze the trajectory of pickled steel over the next decade. Now, let's delve into the key points:

Economic Growth: The overall economic growth of major steel-producing countries and regions (such as China, India, the United States, the European Union, etc.) will significantly impact demand for steel, including pickled steel.

Technological Advancements: Innovations in steel production processes, such as more efficient pickling techniques or alternative materials, could influence production levels.

Environmental Regulations: Stringent environmental regulations regarding emissions and sustainability might lead to changes in production methods and materials used in steel production.

Steel pickling remains a vital step in ensuring the quality and performance of various steel products. While production statistics are elusive, understanding the key applications and emerging trends provides valuable insights into its future trajectory. As advancements in technology and sustainability gain momentum, the future of steel pickling lies in balancing efficiency, quality, and environmental responsibility.